|

|

PDF GS-C200 Data sheet ( Hoja de datos )

| Número de pieza | GS-C200 | |

| Descripción | INTELLIGENT STEPPER MOTOR CONTROLLERS | |

| Fabricantes | STMicroelectronics | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de GS-C200 (archivo pdf) en la parte inferior de esta página. Total 31 Páginas | ||

|

No Preview Available !

GS-C200

GS-C200S

INTELLIGENT STEPPER MOTOR CONTROLLERS

FEATURES

Absolute and incremental positioning

Up to 999,999 step per move

Speed range to 10,000 steps/s

Ramp lenght to 999 steps

Single unregulated supply voltage

Index and velocity mode

Automatic and Home positioning

Loops and Delay execution

Conditional start and stop

Status feedback to the host

RS232 communication port

Point to point and Multipoint protocol

Closed loop operation

Counter preset (GS-C200S only)

Jump to (GS-C200S only)

Jump to on-condition (GS-C200S only)

Initialization during execution (GS-C200S only)

Auxiliary output voltages +5V, ± 12V

DESCRIPTION

The GS-C200 and GS-C200S are powerful stepper

motor control modules that interface every power

sequencer/driver available on the market.

A sophisticated hardware and an easy to learn

programming language result in minimal develop-

ment and debugging time of motion control sys-

tems. The modules are supported by dedicated

software that includes both an on-screen editor and

a debugger that greatly improve the module ease

of use.

The instruction sets comprise respectively 25 (GS-

C200) and 29 (GS-C200S) different commands

which can be executed either under host control or

in a stand alone environment. An on board EE-

PROM is used for program saving and retrieving.

The availability of three User inputs and three

programmable User outputs, each of which can be

tested or set under program control, assures to the

designer a high level of system power and flexibility.

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Vs

Tstg

Top

DC Supply Voltage

Storage Temperature Range

Operating Temperature Range

Humidity (non condensing)

Value

42

– 40 to + 85

0 to + 50

0 to 90

Unit

V

°C

°C

%

June 1994

1/31

1 page

GS-C200 / GS-C200S

The various signals that characterize the GS-C, their function and the active level are described in detail

in the following:

Pin

1-2-3

4-5-6

7

8

9

10

11

12

13

14

15

16

17 - 18

19

20 - 21

22

23

24

25, 29

26

27

Function

The SEL0 (pin1), SEL1 (pin2) and SEL2 (pin3) inputs are used to select the communication protocol and

the module address. They have an internal pull-up and when unconnected they are at the 1 logic level.

The BR0 (pin4), BR1 (pin5) and BR2 (pin6) inputs are used to select the Baud rate of the

communication port. They have an internal pull-up and when unconnected they are at the 1 logic level.

The CHS checksum generation conditioning input enables the user to include or exclude the checksum

character from the data exchange string. A ”zero” logic level applied to this input disables the control and

the generation of the checksum character thus allowing the GS-C to be connected to a video terminal.

This pin is the common terminal for all logic signals and for the power supply return path.

The REC Recall Program Enable input pin, when brought to ”zero”, enables the automatic recall of the

program stored in the EEPROM and its immediate execution.

This pin is for testing purpose only and it must be grounded for normal operation.

The RxD input of the serial communication port is used by the module to receive commands from the

Host Computer. The input logic levels are compatible with the RS232 and V24 standards.

The TxD output of the serial communication port is used by the module to send data to the Host

Computer. The logic levels of this output are compatible with the RS232 and V24 standards.

The TxPD Transmitted data pull-down resistor pin must always be connected to the TxD output (pin 12)

when the Point-to-Point protocol is used. When the Multipoint protocol is selected, this pin must be left

open on all modules except the chain terminator unit, in order to avoid the TxD output overload.

The RDY hardware status output (open collector) signal pin is used as the controller status flag. RDY

assumes a ”zero” logic level when a command or a program is in execution

–12V unregulated output. A maximum of 10mA can be sinked from this pin.

+12V unregulated output. A maximum of 10mA can be sinked from this pin.

Module supply input. For correct operations a supply voltage ranging from 12 to 40 Volt is required.

See pin 8.

5 Volt regulated output, available either for the Sequencer-Driver logic section or for a custom interface

logic supply. The maximum current that can be sinked from this pin is 100mA.

The MOV Motor moving output becomes the logic level ”one” when the GS-C is executing a movement.

This output can be used to program the phase current level when the motion is running at a level higher

than for the rest condition.

The RAMP Ramp in execution output is rised to the logic level ”one” when the GS-C is executing an

acceleration or a deceleration ramp. This output can be used to program the phase current level when

the motion is ramping at a level higher than for the rest or slewing condition.

The ENABLE input pin allows the user to control the Step clock logic output to avoid the motor being

stepped if the previous step was not correctly executed. A ”zero” logic level applied to this pin stops the

generation of the step pulses. This input can be used to stop the system when an emergency occurs, to

execute the motion according to externally generated timing, or to implement a closed loop control

system.

Not connected.

The DIR Direction selection output is used to inform the Sequencer-Driver on the direction of rotation.

The logic level ”one” determines a clockwise rotation, but of course the rotation depends on the motor

phases connection to the Sequencer-Driver.

The RESET Power driver Reset output is brought to the ”zero” logic state for 400µs when the unit is

powered-on, or when the GS-C receives the ”Initialize position counter” command. This output is

normally used to assure the correct start-up of the Sequencer-Driver or any other external custom logic.

5/31

5 Page

GS-C200 / GS-C200S

Error code

1

2

3

4

5

6

Type of error

Parity error when receiving one or more

characters, checksum error, or too long a

command string.

Command argument out of limit or not

requested.

Storage capacity overflow.

Not allowed or not executable command.

Overflow error during program execution

(GS-C200 only).

EEPROM programming error.

The number following the ”V” code depends on the

type of the received command.

When the GS-C answers to a ”V1” request (feed-

back the actual absolute position against the Home

position), the answer will be:

Vxxxxxxx↓

where the xxxxxxx represent the absolute position.

When the GS-C answers to a ”V2” request (feed-

back the USER input/output status), the answer will

be:

Vxy↓

where the x and y meaning is:

x=1

User Input 1 = 1

x=2

User Input 2 = 1

x=4

User Input 3 = 1

y=1

User Output1 = 1

y=2

User Output 2 = 1

x=4

User Output 3 = 1

The logic values of the inputs and outputs are

added together. For example the answer:

V36↓

indicates the following USER I/O status:

UI1 =

UI2 =

UI3 =

1

1

0

3

UO1 =

UO2 =

UO1 =

0

1

1

6

The presence of Checksum character, whose value

is calculated by using the method described in the

previous example, is conditioned by the CHS pin

status.

When CHS is grounded (either by a logic signal or

by a strap to ground) the checksum is deleted.

The string terminator is, as in the previous case, a

Carriage Return.

THE SEQUENCER-DRIVER INTERFACE

The interface to the Sequencer-Driver and, through

it, to the mechanical environment, consists of eight

logic signals (5 outputs and 3 inputs) which enable

the GS-C intelligent controller to interface the GS-

D200 or the GS-D200S modules as well as any

Sequencer Drivers currently available. The eight

signals can be divided into two groups, named

respectively:

PRIMARY SIGNALS

UTILITY SIGNALS

The primary signals are those necessary for the

correct system operation:

RESET Output to reset the Sequencer-

Driver.

CLOCK Step clock output.

DIR Direction output.

ENABLE Step enable input.

The function of each signal is described in detail in

section PIN DESCRIPTION on page 4/31; it will be

shown later that the Step Enable Input in conjunc-

tion with the position sensor of the motor, allows the

implementation of closed loop systems (see para-

graph Closed Loop Operation on pag. 27). The

Utility signals allow the optimization of the driving

system and the minimization of the hardware. They

are:

MOV

Movement in execution output.

RAMP Ramp in execution output.

EOT

Mechanical End of Travel input.

HOME Electrical Home Position input.

By using these signals it is possible to correctly

define the system starting point or reference posi-

tion, or to change the current in the motor windings

during the acceleration and deceleration phases in

order to optimize the motor performance.

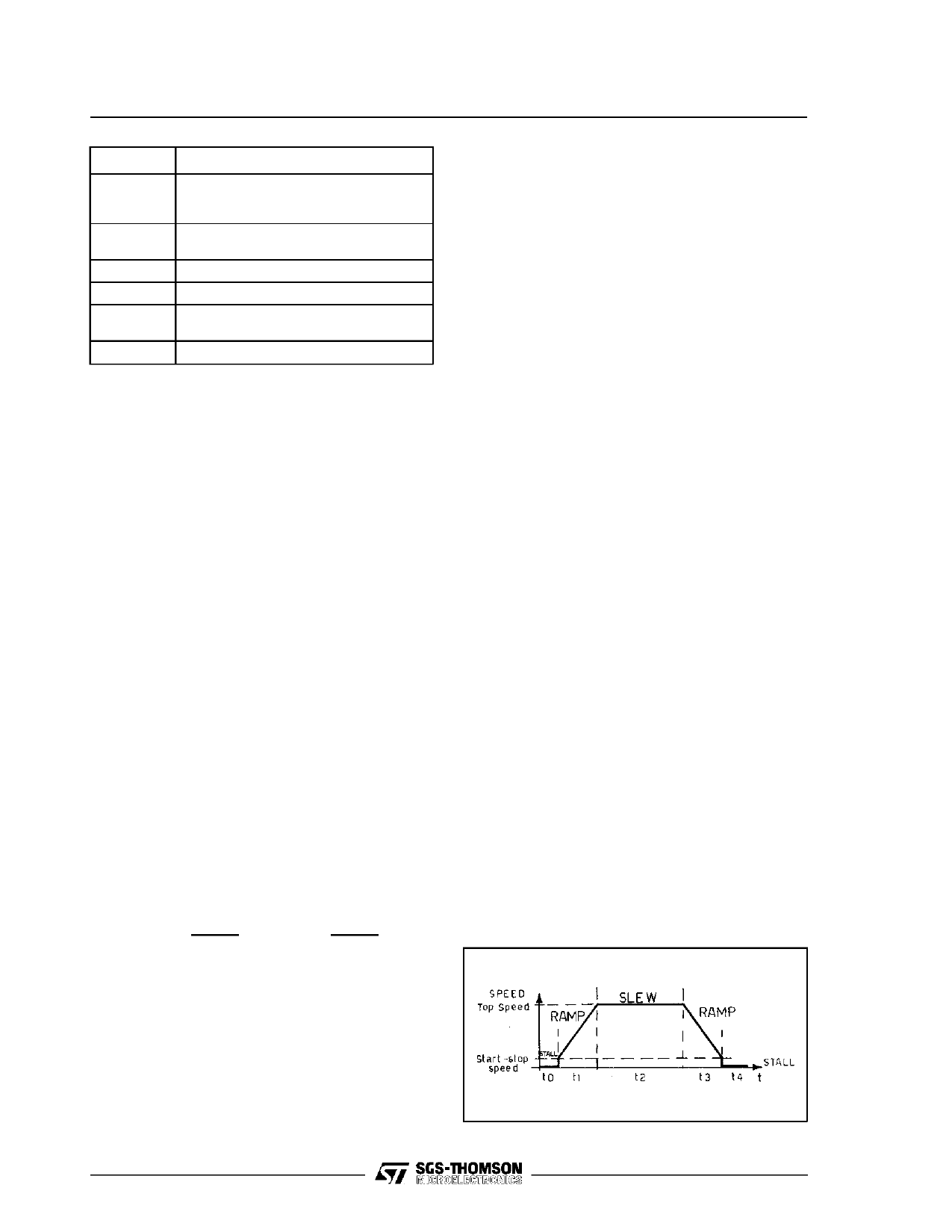

A typical example of the utility signals implementa-

tion is given here. Let’s suppose that the required

speed profile is as shown in fig. 5.

Figure 5. Speed-Time Profile.

11/31

11 Page | ||

| Páginas | Total 31 Páginas | |

| PDF Descargar | [ Datasheet GS-C200.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| GS-C200 | INTELLIGENT STEPPER MOTOR CONTROLLERS | STMicroelectronics |

| GS-C200S | INTELLIGENT STEPPER MOTOR CONTROLLERS | STMicroelectronics |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |