|

|

PDF HMPS-282X Data sheet ( Hoja de datos )

| Número de pieza | HMPS-282X | |

| Descripción | MiniPak Surface Mount RF Schottky Barrier Diodes | |

| Fabricantes | Hewlett-Packard | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de HMPS-282X (archivo pdf) en la parte inferior de esta página. Total 8 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

Agilent HMPS-282x Series

MiniPak Surface Mount

RF Schottky Barrier Diodes

Data Sheet

Description/Applications

These ultra-miniature products

represent the blending of Agilent

Technologies’ proven semiconduc-

tor and the latest in leadless

packaging. This series of Schottky

diodes is the most consistent and

best all-round device available,

and finds applications in mixing,

detecting, switching, sampling,

clamping and wave shaping at

frequencies up to 6 GHz. The

MiniPak package offers reduced

parasitics when compared to

conventional leaded diodes, and

lower thermal resistance.

Package Lead Code Identification

(Top View)

Single

Anti-parallel

3 43 4

2 12 1

#0 #2

The HMPS-282x family of diodes

offers the best all-around choice

for most applications, featuring

low series resistance, low forward

voltage at all current levels and

good RF characteristics.

Note that Agilent’s manufacturing

techniques assure that dice found

in pairs and quads are taken from

adjacent sites on the wafer,

assuring the highest degree of

match.

Parallel

34

21

#5

Features

• Surface mount MiniPak package

– low height, 0.7 mm (0.028") max.

– small footprint, 1.75 mm2

(0.0028␣ inch2)

• Better thermal conductivity for

higher power dissipation

• Single and dual versions

• Matched diodes for consistent

performance

• Low turn-on voltage (as low as

0.34␣ V at 1 mA)

• Low FIT (Failure in Time) rate*

• Six-sigma quality level

* For more information, see the Surface

Mount Schottky Reliability Data Sheet.

Pin Connections and

Package Marking

34

AA

21

Product code Date code

Notes:

1. Package marking provides orientation and

identification.

2. See “Electrical Specifications” for

appropriate package marking.

1 page

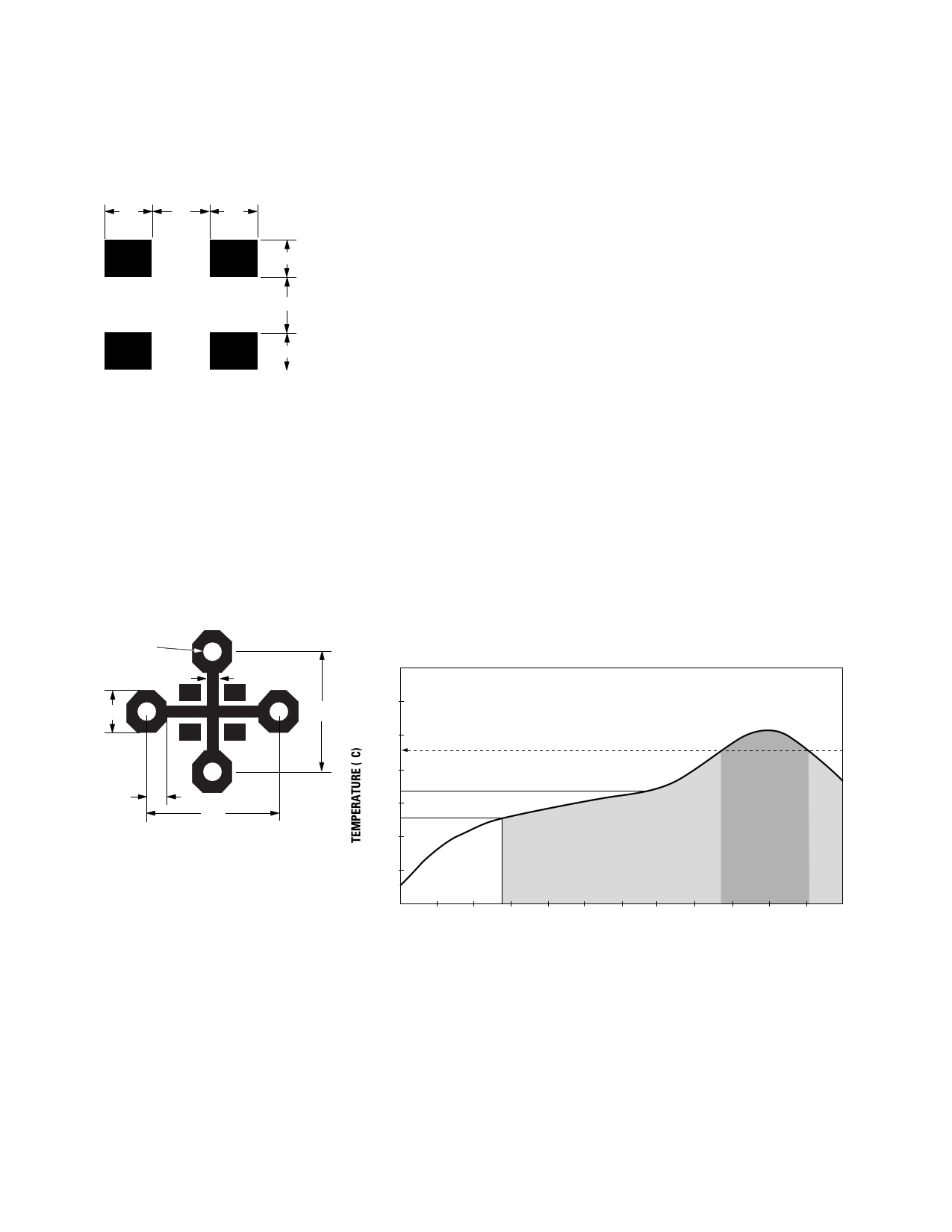

Assembly Information

The MiniPak diode is mounted to

the PCB or microstrip board using

the pad pattern shown in

Figure␣ 10.

0.4 0.5 0.4

0.3

0.5

0.3

Figure 10. PCB Pad Layout, MiniPak

(dimensions in mm).

This mounting pad pattern is

satisfactory for most applications.

However, there are applications

where a high degree of isolation is

required between one diode and

the other is required. For such

applications, the mounting pad

pattern of Figure 11 is

recommended.

0.40 mm via hole

(4 places)

0.20

0.8 2.40

0.40

2.60

Figure 11. PCB Pad Layout, High Isolation

MiniPak (dimensions in mm).

This pattern uses four via holes,

connecting the crossed ground

strip pattern to the ground plane

of the board.

SMT Assembly

Reliable assembly of surface

mount components is a complex

process that involves many

material, process, and equipment

factors, including: method of

heating (e.g., IR or vapor phase

reflow, wave soldering, etc.)

circuit board material, conductor

thickness and pattern, type of

solder alloy, and the thermal

conductivity and thermal mass of

components. Components with a

low mass, such as the MiniPak

package, will reach solder reflow

temperatures faster than those

with a greater mass.

Agilent’s diodes have been quali-

fied to the time-temperature

profile shown in Figure 12. This

profile is representative of an IR

reflow type of surface mount

assembly process.

After ramping up from room

temperature, the circuit board

with components attached to it

(held in place with solder paste)

passes through one or more

preheat zones. The preheat zones

increase the temperature of the

board and components to prevent

thermal shock and begin evaporat-

ing solvents from the solder paste.

The reflow zone briefly elevates

the temperature sufficiently to

produce a reflow of the solder.

The rates of change of tempera-

ture for the ramp-up and cool-

down zones are chosen to be low

enough to not cause deformation

of the board or damage to compo-

nents due to thermal shock. The

maximum temperature in the

reflow zone (TMAX) should not

exceed 255°C.

These parameters are typical for a

surface mount assembly process

for Agilent diodes. As a general

guideline, the circuit board and

components should be exposed

only to the minimum temperatures

and times necessary to achieve a

uniform reflow of solder.

350

Peak Temperature

300 Min. 240°C

Max. 255°C

250

221

200

Reflow Time

150

Min. 60 s

Max. 90 s

100

Preheat 130 – 170°C

Min. 60 s

Max. 150 s

50

0

0 30 60 90 120 150 180 210 240 270 300 330 360

TIME (seconds)

Figure 12. Surface Mount Assembly Temperature Profile.

5

5 Page | ||

| Páginas | Total 8 Páginas | |

| PDF Descargar | [ Datasheet HMPS-282X.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| HMPS-282X | MiniPak Surface Mount RF Schottky Barrier Diodes | Hewlett-Packard |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |