|

|

PDF AD546 Data sheet ( Hoja de datos )

| Número de pieza | AD546 | |

| Descripción | 1 pA Monolithic Electrometer Operational Amplifier | |

| Fabricantes | Analog Devices | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de AD546 (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

a

FEATURES

DC PERFORMANCE

1 mV max Input Offset Voltage

Low Offset Drift: 20 V/؇C

1 pA max Input Bias Current

Input Bias Current Guaranteed Over Full

Common-Mode Voltage Range

AC PERFORMANCE

3 V/s Slew Rate

1 MHz Unity Gain Bandwidth

Low Input Voltage Noise: 4 V p-p, 0.1 Hz to 10 Hz

Available in a Low Cost, 8-Pin Plastic Mini-DIP

Standard Op Amp Pinout

APPLICATIONS

Electrometer Amplifiers

Photodiode Preamps

pH Electrode Buffers

Log Ratio Amplifiers

1 pA Monolithic Electrometer

Operational Amplifier

AD546*

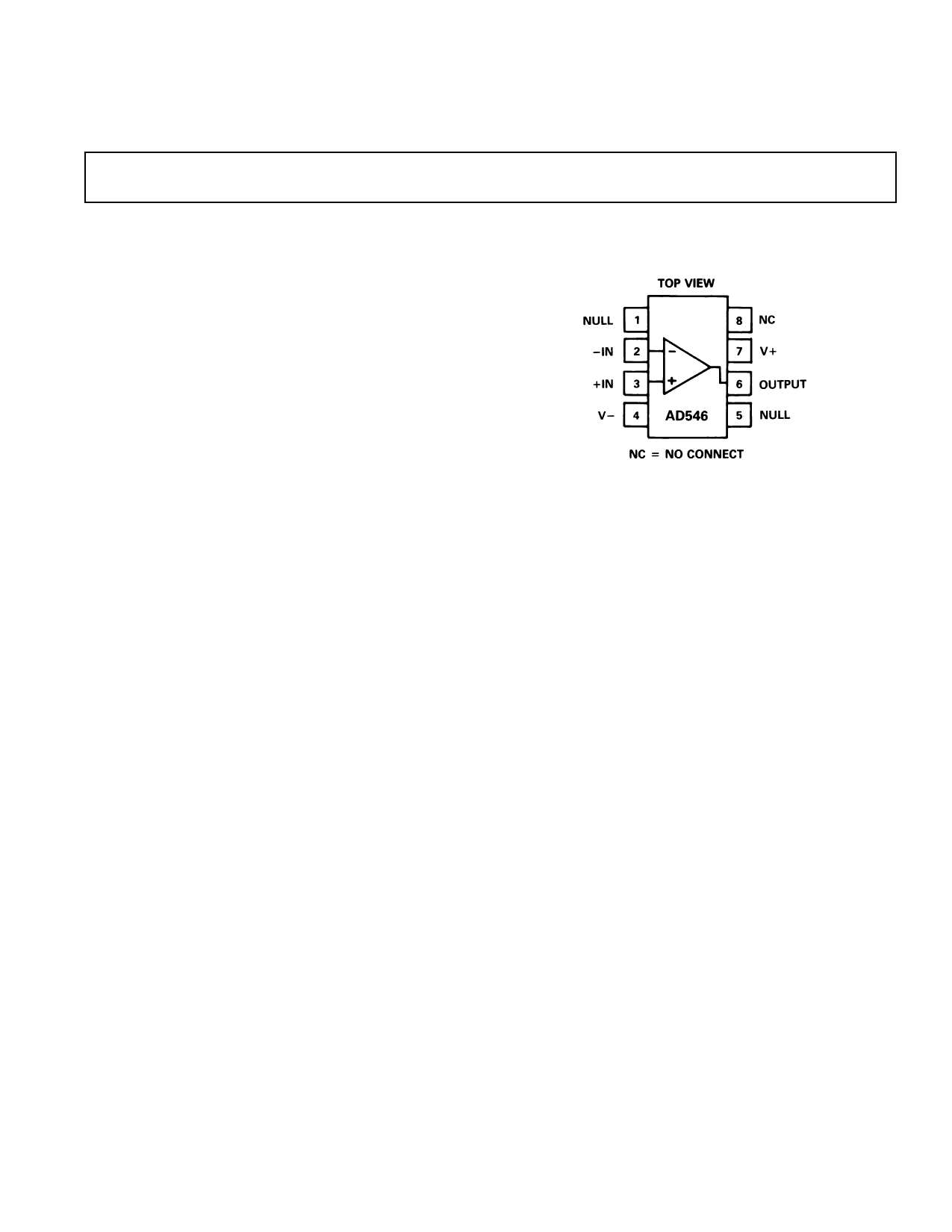

CONNECTION DIAGRAM

8-Pin Plastic

Mini-DIP Package

PRODUCT DESCRIPTION

The AD546 is a monolithic electrometer combining the virtues

of low (1 pA) input bias current with the cost effectiveness of a

plastic mini-DIP package. Both input offset voltage and input

offset voltage drift are laser trimmed, providing very high perfor-

mance for such a low cost amplifier.

Input bias currents are reduced significantly by using “topgate”

JFET technology. The 1015 Ω common-mode impedance,

resulting from a bootstrapped input stage, insures that input

bias current is essentially independent of common-mode voltage

variations.

The AD546 is suitable for applications requiring both minimal

levels of input bias current and low input offset voltage. Appli-

cations for the AD546 include use as a buffer amplifier for cur-

rent output transducers such as photodiodes and pH probes. It

may also be used as a precision integrator or as a low droop rate

sample and hold amplifier. The AD546 is pin compatible with

standard op amps; its plastic mini-DIP package is ideal for use

with automatic insertion equipment.

The AD546 is available in two performance grades, all rated

over the 0°C to +70°C commercial temperature range, and

packaged in an 8-pin plastic mini-DIP.

PRODUCT HIGHLIGHTS

1. The input bias current of the AD546 is specified, 100%

tested and guaranteed with the device in the fully warmed-up

condition.

2. The input offset voltage of the AD546 is laser trimmed to

less than 1 mV (AD546K).

3. The AD546 is packaged in a standard, low cost, 8-pin

mini-DIP.

4. A low quiescent supply current of 700 µA minimizes any

thermal effects which might degrade input bias current and

input offset voltage specifications.

*Covered by Patent No. 4,639,683.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700

Fax: 617/326-8703

1 page

300

250

200

150

+25oC

100

0

5 10 15

SUPPLY VOLTAGE ± VOLTS

20

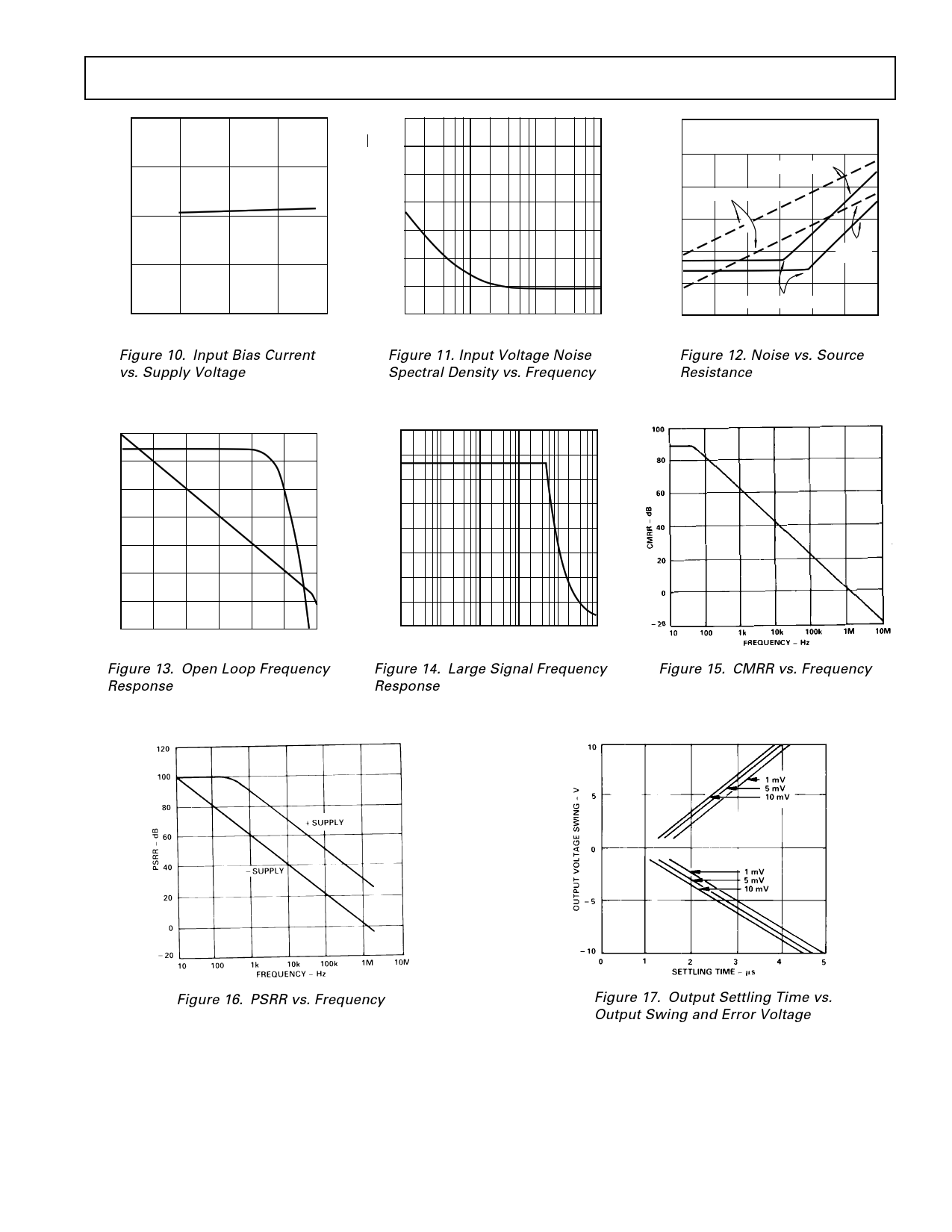

Figure 10. Input Bias Current

vs. Supply Voltage

160

140

120

100

80

60

40

20

10

100

1k 10k

FREQUENCY – Hz

Figure 11. Input Voltage Noise

Spectral Density vs. Frequency

AD546

100k WHENEVER JOHNSON NOISE IS GREATER THAN

AMPLIFIER NOISE, AMPLIFIER NOISE CAN BE

CONSIDERED NEGLIGIBLE FOR THE APPLICATION.

10k

1 kHz BANDWIDTH

1k

RESISTOR JOHNSON NOISE

100

10

10 Hz

BANDWIDTH

1

0.1

100k

AMPLIFIER GENERATED NOISE

1M 10M 100M 1G 10G

SOURCE RESISTANCE – Ohms

100G

Figure 12. Noise vs. Source

Resistance

100 100

80 80

60 60

40 40

20 20

00

–20 –20

–40

10 100 1k

–40

10k 100k 1M 10M

FREQUENCY – Hz

Figure 13. Open Loop Frequency

Response

40

35

30

25

20

15

10

5

0

10 100 1k 10k 100k 1M

FREQUENCY – Hz

Figure 14. Large Signal Frequency

Response

Figure 15. CMRR vs. Frequency

Figure 16. PSRR vs. Frequency

Figure 17. Output Settling Time vs.

Output Swing and Error Voltage

REV. A

–5–

5 Page

AD546

tacting the device under test. Rigid Teflon coaxial cable is used

to make connections to all high impedance nodes. The use of

rigid coax affords immunity to error induced by mechanical vi-

bration and provides an outer conductor for shielding. The en-

tire circuit is enclosed in a grounded metal box.

The test apparatus is calibrated without a device under test

present. A five minute stabilization period after the power is

turned on is required. First, VERR1 and VERR2 are measured.

These voltages are the errors caused by offset voltages and leak-

age currents of the current to voltage converters.

VERR1 = 10 (VOSA – IBA × RSa)

VERR2 = 10 (VOSB – IBB × RSb)

Once measured, these errors are subtracted from the readings

taken with a device under test present. Amplifier B closes the

feedback loop to the device under test, in addition to providing

current to voltage conversion. The offset error of the device un-

der test appears as a common-mode signal and does not affect

the test measurement. As a result, only the leakage current of

the device under test is measured.

VA – VERR1 = 10[RSa × IB(+)]

VX – VERR2 = 10[RSb × IB(–)]

Although a series of devices can be tested after only one calibra-

tion measurement, calibration should be updated periodically to

compensate for any thermal drift of the current-to-voltage con-

verters or changes in the ambient environment. Laboratory re-

sults have shown that repeatable measurements within 10 fA can

be realized when this apparatus is properly implemented. These

results are achieved in part by the design of the circuit, which

eliminates relays and other parasitic leakage paths in the high

impedance signal lines, and in part by the inherent cancellation

of errors through the calibration and measurement procedure.

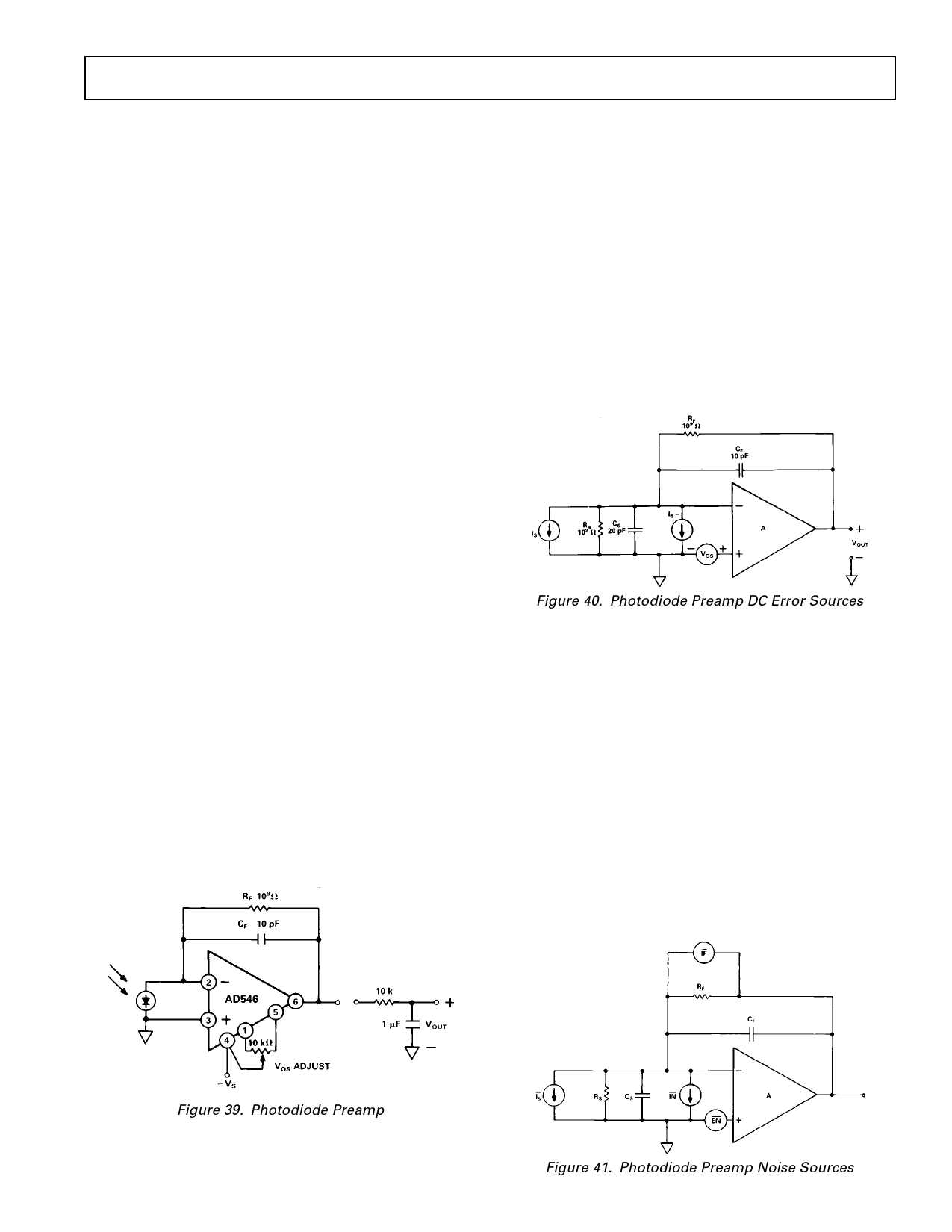

PHOTODIODE INTERFACE

The AD546’s 1 pA current and low input offset voltage make it

a good choice for very sensitive photodiode preamps (Figure

39). The photodiode develops a signal current, IS, equal to:

IS = R × P

where P is light power incident on the diode’s surface in watts

and R is the photodiode responsivity in amps/watt. RF converts

the signal current to an output voltage:

VOUT = RF × IS

Input current, IB, will contribute an output voltage error, VE1,

proportional to the feedback resistance:

VE1 = IB × RF

The op amp’s input voltage offset will cause an error current

through the photodiode’s shunt resistance, RS:

I = VOS/RS

The error current will result in an error voltage (VE2) at the

amplifier’s output equal to:

VE2 = (1 +RF/RS) VOS

Given typical values of photodiode shunt resistance (on the or-

der of 109 Ω), RF/RS can be greater than one, especially if a large

feedback resistance is used. Also, RF/RS will increase with tem-

perature, as photodiode shunt resistance typically drops by a

factor of two for every 10°C rise in temperature. An op amp

with low offset voltage and low drift helps maintain accuracy.

Figure 40. Photodiode Preamp DC Error Sources

Photodiode Preamp Noise

Noise limits the signal resolution obtainable with the preamp.

The output voltage noise divided by the feedback resistance is

the minimum current signal that can be detected. This mini-

mum detectable current divided by the responsivity of the pho-

todiode represents the lowest light power that can be detected

by the preamp.

Noise sources associated with the photodiode, amplifier, and

feedback resistance are shown in Figure 41; Figure 42 is the

voltage spectral density versus frequency plot of each of the

noise source’s contribution to the output voltage noise (circuit

parameters in Figure 40 are assumed). Each noise source’s rms

contribution to the total output voltage noise is obtained by in-

tegrating the square of its spectral density function over fre-

quency. The rms value of the output voltage noise is the square

root of the sum of all contributions. Minimizing the total area

under these curves will optimize the preamplifier’s resolution for

a given bandwidth.

Figure 39. Photodiode Preamp

DC error sources and an equivalent circuit for a small area

(0.2 mm square) photodiode are indicated in Figure 40.

REV. A

–11–

Figure 41. Photodiode Preamp Noise Sources

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet AD546.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| AD5405 | Dual 12-Bit/ High Bandwidth/ Multiplying DAC with 4-Quadrant Resistors and Parallel Interface | Analog Devices |

| AD5410 | Current Source DAC | Analog Devices |

| AD5412 | (AD5412 / AD5422) Current Source & Voltage Output DAC | Analog Devices |

| AD5415 | (AD5424 - AD5547) High Bandwidth Multiplying DACs | Analog Devices |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |