|

|

PDF A1369 Data sheet ( Hoja de datos )

| Número de pieza | A1369 | |

| Descripción | Customer Programmable Linear Hall-Effect Sensor Optimized | |

| Fabricantes | Allegro | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de A1369 (archivo pdf) en la parte inferior de esta página. Total 22 Páginas | ||

|

No Preview Available !

A1369

Customer Programmable Linear Hall-Effect Sensor

Optimized for Use in Current Sensing Applications

FEATURES AND BENEFITS

• Customer programmable offset, and sensitivity

• Sensitivity & QVO temperature coefficients programmed

at Allegro for improved accuracy

• Output value decreases with South Magnetic Field and

increases with North Magnetic field.

• 3-pin SIP package for easy integration with magnetic

concentrator

• Low noise, moderate bandwidth, analog output

• High speed chopping scheme minimizes QVO drift over

temperature

• Temperature-stable quiescent voltage output and

sensitivity

• Precise recoverability after temperature cycling

• Output voltage clamps provide short circuit diagnostic

capabilities

• Under voltage lock-out (UVLO)

Continued on the next page…

Package: 3-Pin SIP (suffix UA)

Not to scale

DESCRIPTION

The Allegro™ A1369 is a customer programmable, high

accuracy linear Hall effect-based current sensor IC. It is

packaged in a thin 3-pin SIPpackage to allow for easy integration

with a magnetic core to create a highly accurate current sensing

module. The programmable nature of the A1369 enables it

to account for manufacturing tolerances in the final current

sensing module assembly.

This temperature-stable device is available in a through-hole

single in-line package (TO-92). The accuracy of the device

is enhanced via programmability on the output pin for end-

of-line optimization without the added complexity and cost of

a fully programmable device. The device features One-Time-

Programming (OTP), using non-volatile memory, to optimize

device sensitivity and the quiescent output voltage (QVO)

(output with no magnetic field) for a given application or

circuit. The A1369 also allow for optimized performance over

temperature through programming the temperature coefficient

for both Sensitivity and QVO at Allegro end of line test.

These ratiometric Hall effect sensor ICs provide a voltage

output that is proportional to the applied magnetic field. The

quiescent voltage output is user adjustable around 50% of the

supply voltage and the output sensitivity is programmable

within a range of 8.5 mV/G to 12.5 mV/G for the A1369-10

and 22 mV/G to 26 mV/G for the A1369-24.

Continued on the next page…

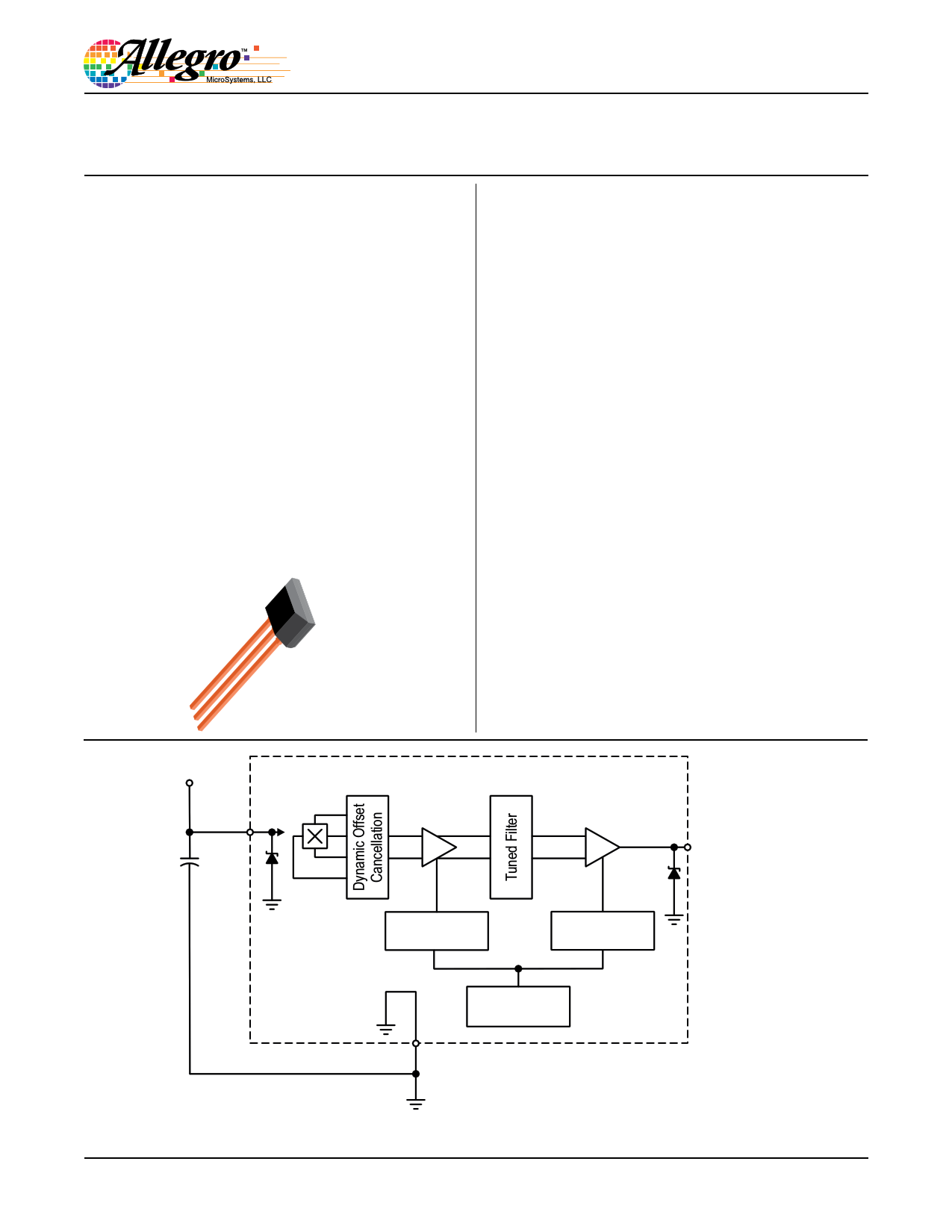

V+

VCC

VOUT/

Programming

Sensitivity and

Sensitivity TC

Offset and

Offset TC

Trim Control

GND

A1369-DS, Rev. 1

Functional Block Drawing

1 page

A1369

Customer Programmable Linear Hall-Effect Sensor

Optimized for Use in Current Sensing Applications

ELECTRICAL CHARACTERISTICS (continued): valid over TA, CBYPASS = 0.1 µF, VCC = 5 V, unless otherwise noted

Characteristic

Symbol

Test Conditions

Min.

Typ.

Max.

Unit

Customer Quiescent Voltage Output Programming

Guaranteed Quiescent Voltage Output

Range7

VOUT(Q)

TA = 25ºC

2.45 – 2.55 V

Quiescent Voltage Output

Programming Bits

− 5 – Bits

Average Quiescent Voltage Output

Step Size8,9

StepVOUT(Q) TA = 25ºC

4.75 7.5 10.5 mV

Quiescent Voltage Output

Programming Resolution10

ErrPGVOUT(Q) TA = 25ºC

–

StepVOUT(Q)

× ±0.5

Customer Sensitivity Programming

Sensitivity Programming Bits

– 7 – Bits

Default Sensitivity

Guaranteed Fine Step Sensitivity

Range11

Average Sensitivity Step Size8,9

Sens

Sens

StepSens

A1369-10, TA = 25ºC

A1369-24, TA = 25ºC

A1369-10, TA = 25ºC

A1369-24, TA = 25ºC

A1369-10, TA = 25ºC

A1369-24, TA = 25ºC

Sensitivity Programming Resolution10 ErrPROGSENS TA = 25ºC

−

−

-8.5

-22

-72

-163

–

-10.5

-24

–

–

-102

-233

StepSens

× ±0.5

−

−

-12.5

-26

-133

-303

–

mV/G

mV/G

mV/G

mV/G

µV/G

µV/G

µV/G

Customer Clamp Disable Programming

Clamp Disable Bit

– 1 – Bit

Output Voltage12

Customer Lock

VSAT,HIGH

VSAT,LOW

B = -X G;

RL = 4.7 kΩ (VOUT to GND)

B = + X G;

RL = 4.7 kΩ (VOUT to GND)

4.75 – – V

– – 0.25 V

Overall Programming Lock Bit

LOCK

– 1 – Bit

Continued on the next page…

7VOUT(Q)(max) is the value available with all programming fuses blown (maximum programming code set). VOUT(Q) is the total range from VOUT(Q)init up to and includ-

ing VOUT(Q)(max). See Characteristic Definitions.

8Step size is larger than required to account for manufacturing spread. See Characteristics Definitions

9Non-ideal behavior in the programming DAC can cause the step size at each significant bit rollover code to be twice the maximum specified value of StepVOUT(Q) or

StepSENS

10Fine programming value accuracy. See Characteristic Definitions

11Sens(max) is the value available with all programming fuses blown (maximum programming code set). Sens range is the total range from Sensinit up to and including

Sens(max). See Characteristic Definitions.

12 VSAT,HIGH and VVSAT,LOW will scale with the supply voltage due to the Ratiometry of the part

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

5 Page

A1369

Customer Programmable Linear Hall-Effect Sensor

Optimized for Use in Current Sensing Applications

PROGRAMMING GUIDELINES

Overview

Programming is accomplished by sending a series of input volt-

age pulses serially through the VOUT pin of the device. A unique

combination of different voltage level pulses controls the internal

programming logic of the device to select a desired programma-

ble parameter and change its value. There are three voltage levels

that must be taken into account when programming. These levels

are referred to as high (VPH), mid (VPM), and low (VPL).

The A1369 features a Try mode, Blow mode, and Read mode:

• In Try mode, the value of multiple programmable parameters

may be set and measured simultaneously. The parameter

values are stored temporarily, and reset after cycling the

supply voltage.

• In Blow mode, the value of a single programmable parameter

may be permanently set by blowing solid-state fuses

internal to the device. Additional parameters may be blown

sequentially. This mode is used for blowing the device-level

fuse, which permanently blocks the further programming of all

parameters. Device locking is also accomplished in this mode.

• In Read mode, the current state of the programming fuses can

be read back for verification of programmed value.

The programming sequence is designed to help prevent the device

from being programmed accidentally; for example, as a result

of noise on the supply line. Although any programmable vari-

able power supply can be used to generate the pulse waveforms,

Allegro highly recommends using the Allegro Sensor Evaluation

Kit, available on the Allegro Web site On-line Store. The manual

for that kit is available for

Definition of Terms

Register. The section of the programming logic that controls the

choice of programmable modes and parameters.

Bit Field. The internal fuses unique to each register, represented

as a binary number. Incrementing the bit field of a particular

register causes its programmable parameter to change, based on

the internal programming logic.

Key. A series of mid-level voltage pulses used to select a register,

with a value expressed as the decimal equivalent of the binary

value. The LSB of a register is denoted as key 1, or bit 0.

Code. The number used to identify the combination of fuses

activated in a bit field, expressed as the decimal equivalent of the

binary value. The LSB of a bit field is denoted as code 1, or bit 0.

Addressing. Incrementing the bit field code of a selected register

by serially applying a pulse train through the VCC pin of the

device. Each parameter can be measured during the addressing

process, but the internal fuses must be blown before the program-

ming code (and parameter value) becomes permanent.

Fuse Blowing. Applying a high voltage pulse of sufficient

duration to permanently set an addressed bit by blowing a fuse

internal to the device. Once a bit (fuse) has been blown, it cannot

be reset.

Blow Pulse. A high voltage pulse of sufficient duration to blow

the addressed fuse.

Cycling the Supply. Powering-down, and then powering-up the

supply voltage. Cycling the supply is used to clear the program-

ming settings in Try mode.

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

11

11 Page | ||

| Páginas | Total 22 Páginas | |

| PDF Descargar | [ Datasheet A1369.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| A1360 | PNP Transistor - 2SA1360 | Toshiba |

| A1360 | Low-Noise Programmable Linear Hall Effect Sensor ICs | Allegro |

| A1361 | Low-Noise Programmable Linear Hall Effect Sensor ICs | Allegro |

| A1362 | Low-Noise Programmable Linear Hall Effect Sensor ICs | Allegro |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |